Compared with end-milling, flycutting is often cited as the slower and therefore inferior process for milling flat surfaces. Whilst this opinion may hold water for industrial scale work, where large volumes of material must be removed at the minimum cost, for finishing cuts in the smaller workshop, flycutting is by far the better bet.

Unlike expensive endmills, your flycutter will last indefinitely. A dulled cutter can be brought back to perfection on the bench grinder by sharpening just one face. The cutting diameter can be adjusted to any surface up to 7" [175mm] wide, allowing a finishing cut to be made in just one pass. Provided the head of your miller is trammed square to the table, the resultant surface is both uniform and flat. With a light cut and a slow, consistent feed, the finish obtained on steel, iron and non-ferrous materials can look as if it has been surface ground!

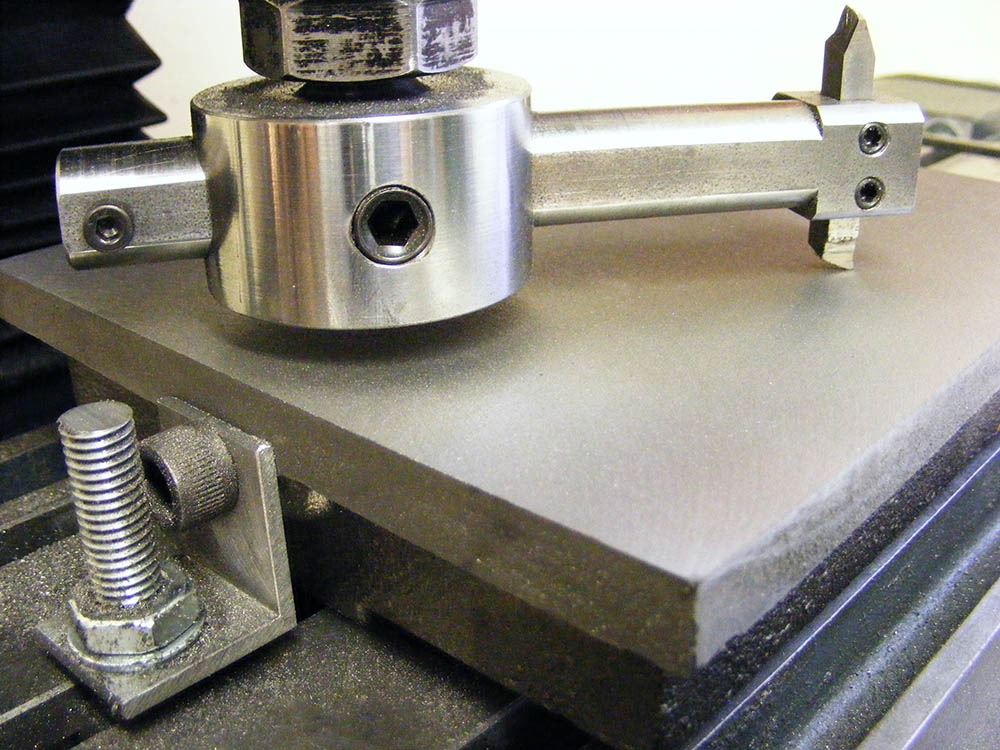

This design is very sturdy and the body includes an integral parallel arbor to be gripped with a collet in the miller or lathe. The kit arrives with all necessary materials together with a square 1/4" HSS toolbit. The arm, produced from 3/4" square bar, is a particularly interesting and satisfying component to manufacture!

Click the Extended Information tab to learn a little more.